We do all our detailing using CADS-RC or RebarCAD software which has been specifically developed for the UK and US markets and have experience in both building structures and civil works (bridges and roads). The bar bending schedules are produced automatically from the drawings, reducing the likelihood of errors in transferring information from drawing to schedule and allowing changes to be made easily. Our drawings and schedules are customized with our client's title block and logo and graphic preferences.

The detailing instructions giving the reinforcement to be used can be conveyed as sketches or mark-ups on the engineer's drawings, or in the form of contours from a computer software programme.

Teczoom drawings prepared with CADS-RC or RebarCAD can be read by anyone with Autocad software. Bar bending schedules can be issued as PDF files, Excel files (which allow you to make changes later) and SDI files which can be used electronically in the manufacturing process.

With most of our clients communication takes place by e-mail, although we are able to set up shared space if you prefer. All queries from us are recorded in a RFI form (Request for Information) that we maintain up to date. This allows both parties to keep track of all communication in one location.

Reinforcement Detailing (UK)

Production of reinforced concrete detail drawings to British, American and Eurocodes using design information from our clients. We follow the relevant standards and best practice. This includes documents such as Eurocode 2 (British Standard 8110), BS 8666:2005 and the IStructE Standard Method of Detailing Structural Concrete. We normally charge our clients based on the number of drawings produced.

Rebar Detailing and Estimating (USA)

In the USA, we use the American Concrete Institute’s Details and Detailing of Concrete Reinforcement. Sometimes requested by US rebar fabricators at tender stage, we can prepare an estimate of the quantity of reinforcement steel that will be required in a project. The client provides the structural General Arrangement drawings and the Reinforcement Detailing Instructions (RDI). From this we work out for each bar the weight of steel and provide a summary of the tonnage of steel for the whole job.

Our output to the client is an Estimation Take Off Report, a simplified bending schedule prepared as an excel document that is sufficiently accurate for bidding purposes, but is less accurate than when the bar bending schedule is prepared from a completed detail drawing. Our fee for this is based on the total tonnage of steel.

Structural Frame Measurements / Take - offs

Our clients for this service are UK construction companies who use measurements in preparing their tenders. Working from the Architect's and Engineer's drawings, our quantity surveyors prepare Bills of Quantities and measure the quantities. We can do this using paper copies or preferably Autocad drawings.

We follow SMM7 rules of measurement and normal British practice. We produce our bills as Excel document, and for some clients we use Esti-mate software, and can also use other software to suit our client's systems.

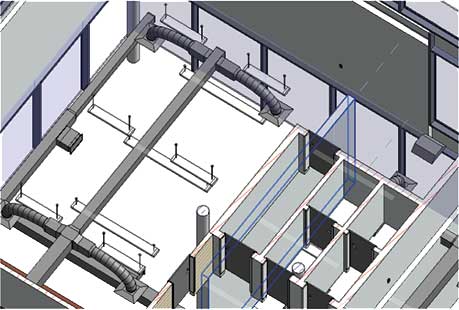

Building Information Modeling (BIM)

Building Information Modeling is a digital representation in 3 dimensions of the physical and functional characteristics of a building that integrates the architecture, the structure and the building services in one model and leads to more informed decisions at the time of the design and during the lifetime of the building. Its main benefits are to evaluate constructability and design intent and to identify potential clashes between various elements (such as structure and services) before the start of construction.

Our clients are often construction companies who want to iron out potential problems before they occur on site. We use Revit software from Autodesk which is Autocad compatible and we normally bring together the drawings prepared by the consultants into one 3D model. We highlight potential clashes and obtain instructions from the client to resolve them.